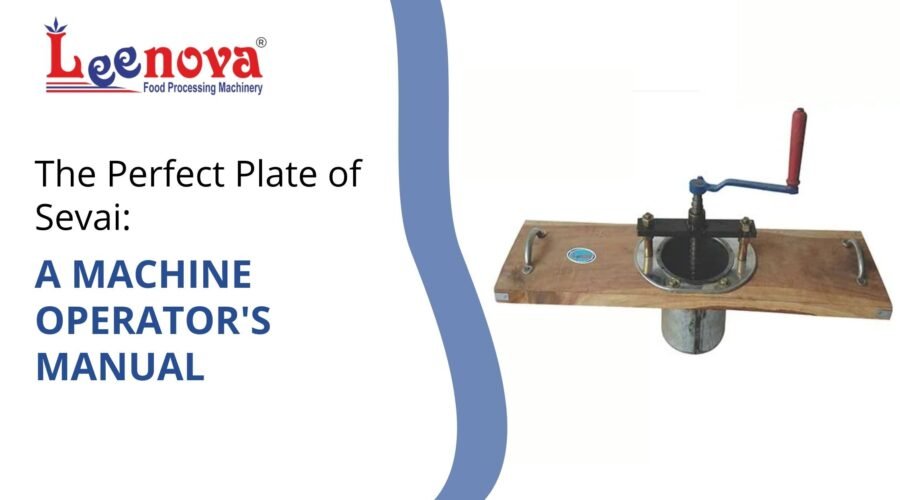

A Leenova sevai machine makes the process of preparing sevai (rice vermicelli) efficient and consistent for home cooks and commercial kitchens alike, unlocking productivity, hygiene, and premium results over manual methods.

Introduction: The Rise of Sevai Automation

Switching to a sevai machine transforms traditional, labor-intensive sevai making into a streamlined, operator-friendly process that ensures safety, speed, and uniform output.

Pre-Operation Checklist: Setting Up the Machine

Before beginning, ensure all bolts are tightened, gears are lubricated with food-grade grease, and brass dies (jalis) are correctly positioned—large holes facing up, smaller ones down for proper sevai extrusion.

Ingredients and Dough Preparation

For perfect sevai, use wheat flour (or preferred grain) and add minimal water to form a slightly soft, semi-moist dough. This ensures smooth extrusion and prevents machine clogging.

Loading the Machine and Initial Operation

Place the prepared dough into the machine’s hopper while running. Feed the dough gradually, avoiding over-filling. Leenova machines can efficiently process 30–50 kg of dough per hour, depending on the model and operator experience.

Cooling and Chamber Maintenance

Add small amounts of water to the machine’s side compartment at intervals to keep the chamber cool, preventing dough from sticking or overheating. Collect the hot water expelled separately for food safety.

Safe Removal and Cleaning

Once production is complete, immediately remove the brass dies (jalis) and soak them in water. This prevents dough from hardening and makes cleaning easier. Ensure the main chamber and all attachments are thoroughly cleaned before storage to protect machine longevity.

Production Capacity and Commercial Benefits

Leenova sevai machines are designed for commercial output, with capacities ranging from 30 to 100 kg per day. Features include stainless steel bodies for food safety, energy-efficient motors, and ergonomic handles or switches for effortless operation.

Maintenance and Troubleshooting Tips

- Lubricate gears regularly with non-toxic grease.

- Check for and tighten any loose nuts or bolts.

- Ensure dies are free from old dough buildup.

- Seek professional servicing in case of abnormal noise or reduced output.

Safety Precautions for Operators

- Always disconnect from the power supply before cleaning or maintenance.

- Train all users on correct feeding, handling, and emergency shutdown.

- Use provided tools—never use bare hands inside the hopper when operating.

Why Choose Leenova Kitchen Equipment Pvt. Ltd.?

Leenova machines offer:

- Durable construction with high-grade stainless steel

- Low maintenance with easy-to-disassemble parts

- Multiple die options for versatile sevai shapes

- ISO certification for assurance of food safety and manufacturing standards

Frequently Asked Questions

- Can the machine handle gluten-free doughs? Yes, with proper consistency adjustment.

- Are spare parts easily available? Leenova assures fast delivery and support for all essential parts.

- Is the machine suitable for bulk production? Commercial models cater to large-scale kitchens and food businesses.

Conclusion: Make Perfect Sevai Every Batch

Mastering the operation, care, and maintenance of the Leenova sevai machine guarantees consistent, hygienic sevai—boosting both productivity and customer satisfaction in any kitchen.