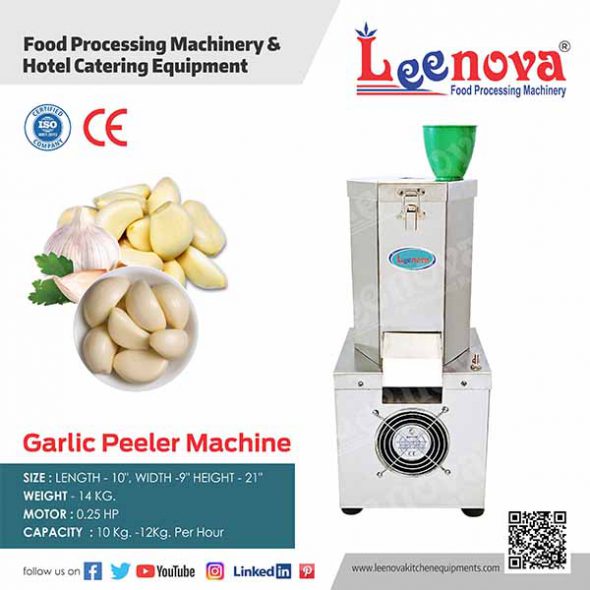

Garlic, with its unique flavour and numerous health benefits, is a staple ingredient in many culinary dishes. However, peeling garlic cloves can be a time-consuming and tedious task. This is where Garlic Peeling Machine come to the rescue, offering an efficient solution to streamline the process and enhance productivity. Categories: Catering Equipment, Food Processing Machinery, Hotel Equipment. Using a Garlic Peeling Machine: Preparation: Begin by selecting fresh garlic cloves and removing any loose outer layers. Load the cloves evenly into the feeding tray of the machine. Operation: Activate the garlic peeling machine, allowing it to perform its automated peeling process. The machine

Garlic Peeling Machine